Damen opens a new stage in the development of 3D-printing. With the help of this technology, the Dutch shipyard has created the world's first marine propeller.

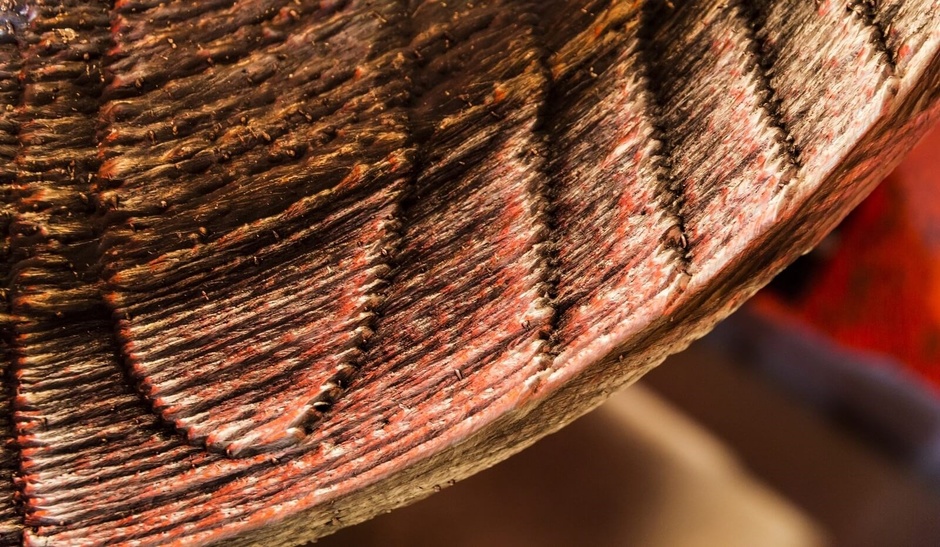

The prototype, called WAAMpeller, was produced on the basis of a computer 3D model using the WAAM (Wire Arc Additive Manufacturing) method.

The essence of the process is that nickel-aluminum bronze alloy (NAB) wire is layered on a tooling and fused with an electric arc.

Printed in RAMLAB's lab in the port of Rotterdam, the 1.3-meter propeller will travel to Birmingham, UK for final machining at Autodesk's production center.

The project has led to discoveries that have broadened the understanding of material properties and could lead to a breakthrough in the industry.

Developers are optimizing the process and are also aiming to create more complex designs. If serial 3D printing of propellers can be launched, their production will become much simpler and faster.

The finished prototype is planned to be used only for demonstration purposes. But Damen Sipyards is starting to build a second BV-class propeller next month, and promises to have it installed on one of its tugboats by the end of this year.

3D printing is increasingly being used in shipbuilding to produce parts for boats. For example, Jim Smith from Grass Roots has assembled a kayak in this way.