The hydraulic system, consisting of oil-filled pipes, fittings, pumps and hydraulic equipment, is the workhorse most yachtsmen dream of.

It does not require much attention, but makes a lot of useful things on board. A hydraulic winch, for example, usually works without overheating from sunset to sunrise. The same goes for the hydraulic bow thruster; however, if you want it to work forever, work on your parking skills. The lifeboat and hydraulics are as inseparable as Boston and Whaler, together they can easily pull a heavy tender out of the water. Should we mention the benefits of hydraulic stabilisers when the passengers' faces turn green like young foliage when they're rocking?

At first, there were water mills, whose wheels were rotated by water under the influence of gravity forces. Armed with a sufficient number of belts and blocks, a person who was not deprived of the engineer's ingenuity could find the rotating axis of the watermill wheel in many applications.

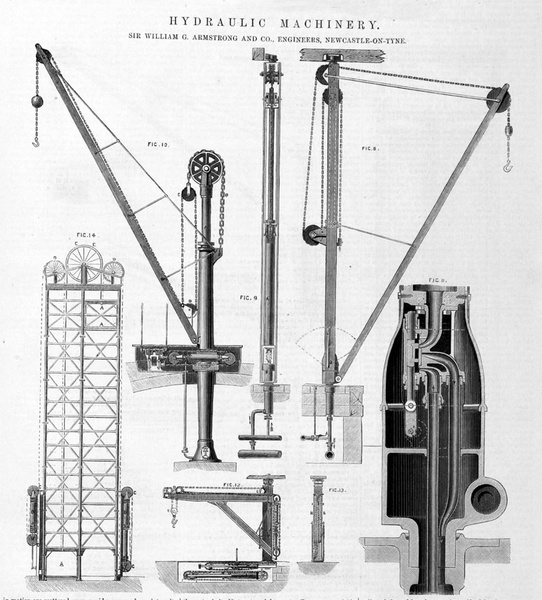

In the mid 19th century, at the height of the industrial revolution, Englishman William Armstrong invented how to apply hydraulics to cranes in the busy port of Newcastle-upon-Tyne. The system was pressurized from a nearby water tower. Later, he invented a hydraulic accumulator, which was a water tank with a heavy ram on top. The ram was lowered and its weight created the necessary pressure in the pipeline. The principle of its operation can be compared to that of a medical syringe.

Nowadays pumps provide pressure on ships and equipment is made of modern materials and with high accuracy, but the principle has not changed a bit. Hydraulic systems mostly use oil as a working fluid. They are a closed system and consist of oil tank, pipelines, pistons, rods and other equipment. The general principle of operation is based on the incompressibility of the fluid. The pump, creating pressure at one end of the system, distributes it to the whole system regardless of its size. At the other end of the pipeline is connected equipment that is susceptible to pressure changes in the system, for example, the hydraulic cylinder of the steering device. A change in pressure in the system will force the hydraulic cylinder to move, doing a certain job, in this case turning the steering pen.

Usually hydraulic drive in all its manifestations can be found on large yachts, where it has found wide application, and on smaller yachts it is used only for the steering device and transom plates. No matter how complex the systems are, they need to be maintained so that they do not have to be repaired later.

The basics are described below, but remember that the best source of practical information is an experienced mechanic.

Checking the oil

Some yachts have only one hydraulic pump in the engine room. When stabilizers, bow thrusters, sloops, ladders are fed with one pump, this system is called integrated. They are made to order and one of the features is that they are self-contained electrically, independent of the main engine. This layout is considered to be a reference and maintenance is simplified, since only one system has to be monitored.

But more often than not you can see standalone devices that require more excitement. Each mechanism will have its own pump, or it will be powered by adjacent mechanisms that rarely work together, such as the bow thruster and windlass.

And now the first rule. Regardless of the device of your system, control the oil level.

It is done elementary, given that with the correct installation of leaks are rare, and any change in level is easy to see in the sight glass, and you do not have to spin and measure anything with a ruler.

If the oil level does drop, refill it and immediately find and fix the cause of the leak. In case of asphyxiation, the equipment will not work as responsively as before, or will stop listening at all, and everything that was spilled will go to the hold (and therefore to the drying pumps).

When you refill the oil, use a clean funnel and it will not be superfluous to pass it through a paper filter.

Take a sample

Second in line is the oil purity clause. It will not be superfluous if you make an effort to keep it almost in sterile conditions. Which means that you should only open the equipment if necessary.

Each year, or at six-month intervals for large motorcycle hours, take oil samples from the systems and send them to the laboratory for analysis. The oil should remain the same color as it was during operation, at least a little darker. Even if it looks good, let it be examined in the lab anyway.

This problem is particularly common with stabilizers that are constantly running on the move and sometimes in the parking lot.

Black oil becomes because of impurities in it. Excessive wear of pumps can cause metal dust in the oil. This will mean that the pumps must be repaired or replaced. Another indicator that there is a problem somewhere is the presence of water and dirt in the sample. A detailed description can be obtained from the lab findings. All of this may mean that oil and filters need to be changed, or the system needs to be refilled and flushed, but the decision should be made after consulting with the craftsmen.

The oil should be changed during the period recommended in the manufacturer's manuals, or more often if the oil has been overheated or impurities are visible in it. Naiad recommends oil changes every three years for its products, or every 4,000 engine hours for stabilizers and every three years for thrusters. Shaft seals on pumps are changed in the same mode.

Just as important is the timely change of filters. Usually, the need to replace them is determined by the operating pressures.

Save it to . «coolness»

If the hydraulic equipment operates with virtually no stops (stabilisers, for example), the oil will become very hot. In this case it is necessary to run it through the cooling system. Therefore, the maintenance of the outboard cooling system is added. Therefore, change the impellers on the circulation pumps according to the schedule, monitor the flow through the kingston grilles, the condition of the anode protection and the heat exchanger every month. Do not hesitate to contact a professional for advice in case of doubt.

To prevent this, check the oil temperature regularly while the stabilizers are running.

Steering machines

Not every board has such an advanced system as described above. Most yachts have only hydraulic steering machines. Problems rarely happen unless someone comes to the tiller room and drops something heavy on the hydraulic cylinder.

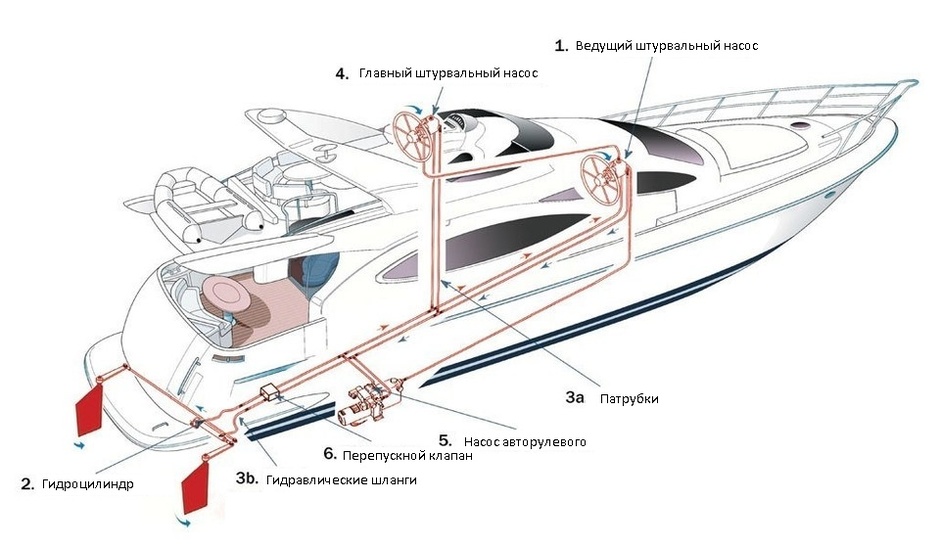

Usually the hand wheel is connected to the pump (two-line system), but there are also pressure systems (three-line). The second variant is a bit more complicated, as additional equipment is included in the system, but it is equally reliable and easy to maintain.

The only thing that can make them go down there is bad pen responsiveness when the helm starts to spin tightly, and similar things. This is mainly due to low oil levels or air in the system. The easiest and cheapest way to solve such a «serious» problem is to refill the oil (it will not take much).

With a direct connection to the pump, fill at the highest point of the system, and when using a pressurized system, simply refill into the consumable tank.

In a two-line system, the fluid is moved only by gravity forces, including between handwheels. A bypass between the two handwheels allows oil to flow downwards and the air to rise up and out through the air valve at the top of the system. In most systems, simply unscrew the plug and carefully refill the oil or use a threaded tube. It is unlikely that much oil will be needed.

If a lot of air has entered the system or if the oil level has fallen heavily due to a leak in the damaged hydraulic cylinder, or, as I had a few years ago, due to incorrect installation of the steering wheel pump (I called the «expert») - you will have to refill the system. This is more complicated and it will take one more hand.

The oil re-fill procedure itself is carried out in the following way: one turns the handwheel as quickly as possible in one direction, throwing out the oil through the drain pipe, and the other collects everything that is poured out. Then a new one, but already in the other direction. In the manual there will be more detailed instructions for your steering car.

The bigger yachts will be equipped with a three-line system. This system is filled through a separate pressure vessel. These systems are technically more complex, but easier to check and refill. All you do is add oils to the tank by bleeding the pressure. When you're done, pump the compensator back in with a normal air pump.

When the system is full, you should get rid of air in the system by turning the handwheel in both directions several times. Then find the leaks. To do this, apply pressure by pushing the helm at the end of the rudder pen movement. During this time, your assistant should wipe all connections and mechanisms with paper and make sure they are tight. Move the steering wheel and do the same.

If you find a leaky connection and you fail to press it, you will have to replace the entire area. But if the hydraulic cylinder seal is leaking, it's much worse. Its replacement is done with dismantling in the clean shop, because the appearance of impurities in the oil is a problem for the simplest hydraulic system, not to mention the intricately woven systems on board megayachts.

This article was published in October 2017 in Power & Motoryacht magazine. It was written by Mike Smith. For a translation of another article by Mike Smith on bilge maintenance and dehumidification equipment, read it here.