So, you've selected a boat and you're going to put an outboard on it. It's easy for a non-specialist to get confused by the plethora of outboard models. Similar, at first sight, models may in fact seriously differ from each other.

To choose the right one, the buyer should not be guided by the number of horsepower and the size of the engine. We will have to deal with a litre, the number of cylinders, differences of two-stroke engines from four-stroke, carburetor engines from injector engines, and direct fuel injection systems from electronic ones.

Here's what all those parameters mean to the engine and how not to break your head reading the outboard's data sheet.

How big or small should an outboard motor be?

The power of modern outboard engines ranges from 2 to 450 hp.(Mercury Racing 450R). There is still, however, the Seven Marine 627SV, whose power output is 627 hp, but the Volvo Group, which includes the brand, announced in the fall of 2020 that it is going to discontinue their production.

Engine power depends on two main parameters: the number of cylinders and the litre. The litre is also referred to as «working volume» of the engine. It is the sum of the displacements of all the cylinders and is calculated on the basis of their cross-section and the length of the piston stroke. The cubic capacity indicates how much fuel an engine can burn in one cycle.

If a manufacturer wants to increase an engine's power, they have two options: increase the number of cylinders or increase the cylinder displacement.

The tiny Yamaha 2 DMHS with 2 hp has just one cylinder and a displacement of 50 cm³ (0.05 liters). The powerful Mercury Racing 450R has eight cylinders and a displacement of 4.6 liters. For comparison, an engine of the same displacement is used on the BMW x5 cars.

The engine cylinders can be positioned either on one side or opposite each other at an angle (in which case the letter V appears in the model name).

«How many horses can» the boat - depends on each particular model. And overdoing it and putting too powerful motor on the boat is not at all better than putting an underpowered one. If the engine power is too high, the transom on which the engine is attached may collapse or break off from the hull.

The boatyard always tells the future owner what minimum and maximum engine power the boat is designed for.

Optimal is considered to be the ratio of 1hp for every 20-25 kg of weight of the loaded boat.

Small and simple RIB and PVC boats are often enough to have 5 hpengines.

But even in this case, maximum power and hull length are not always the same. For example, 3-meter RIB Brig Falcon 300 comes with outboard Honda BF 4 times more powerful - 20 hp (although the owner can stop at the options and capacity of 4-15 hp) at 4-meter RIB Boston Whaler 130 Super Sport put Mercury ELPT EFI capacity of 25-40 hp.

On 5-meter aluminum fishing boat NorthSilver 545 Fish maximum power of the engine is already over a hundred and comes up to 115 hp.

6-meter fiberglass bowrider Jeanneau Cap Camarat 6.5 BR in maximum configuration boasts Yamaha F200 FETL with 200 hp. The minimum for this model is 130 hp. Another meter increase the length of the hull, and we find already up to 250 «heads» « in the herd» 7.1-meter aluminum boat Volzhanka Voyager 700.

Almost the most powerful outboards (up to 425 hp) are mounted on 8-meter boats (for example, a boat with a center console Chris-Craft Catalina 27). Though you can limit 200 hp on the specified model, such boat won't get far to the absolute maximum, 450 hp per one engine.

«The most powerful outboards are already found on 9,6-meter» with trawler Grizzly 960 Unimog. It needs a total of 900 hp, and this is achieved by installing either a pair of 450 hp or three 300 hp engines.

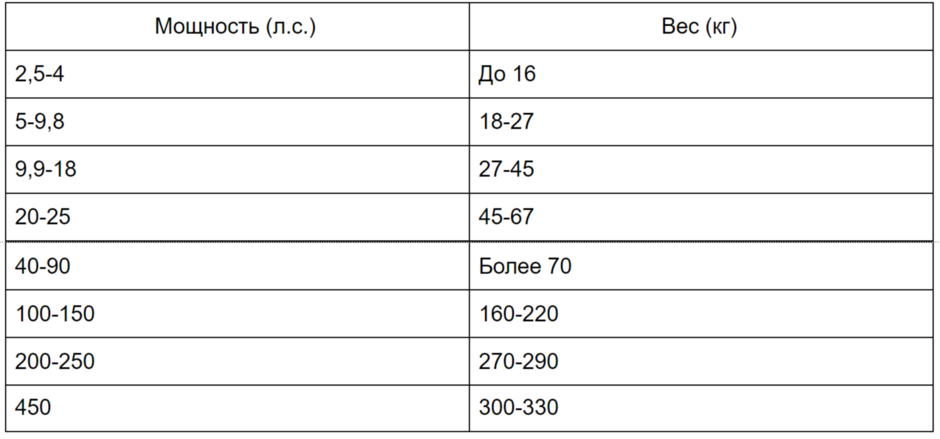

Engine weight depending on capacity

Two-stroke and four-stroke outboard engines have different power ratings.

Another important engine characteristic is how many times the cylinder piston lowers in one cycle. This determines how the cylinder chamber is cleaned from the exhaust gas and filled with fuel: at the same time or in two stages.

In terms of this parameter, engines are divided into two-stroke and four-stroke engines.

Two-stroke engines weigh less and, due to their simpler design, are easier to maintain. They are not so picky about fuel quality.

With the same engine displacement, a two-stroke will be slightly more powerful than a four-stroke.

While two-stroke engines are up to 30-40 percent cheaper, they are noisy and use 20 percent more fuel than a four-stroke.

Moreover, due to the tendency to grease the spark plugs, they do not run smoothly, especially at low and idle speeds. Although, the manufacturers are trying to minimize all these disadvantages on modern models.

The majority of low-powered outboard motors (2.5-4 hp) have two strokes. Though such system can be found on models with power up to 250 hp.

First of all, four-stroke engines are much more popular due to their fuel efficiency. Moreover, they are quieter and more environmentally friendly.

They have a more complex design, so they are heavier and their maintenance is not as easy as for two-stroke engines.

For fuel quality, four-stroke engines are also more demanding. But they don't have to mix petrol and oil.

That can be a problem during transport.

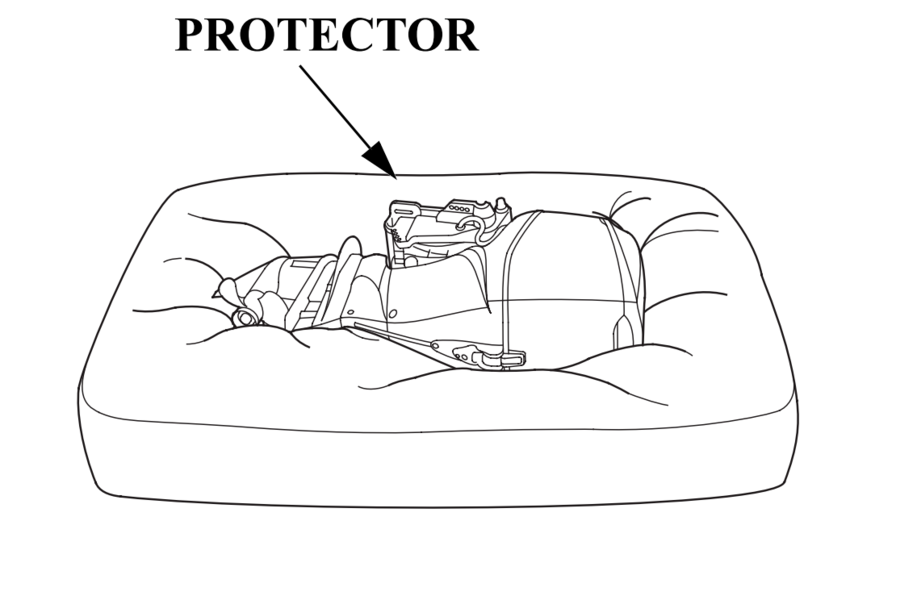

The two-stroke engine can be transported in any position, but the four-stroke can be transported vertically or at one certain side.

If you don't follow these recommendations, oil will get into the combustion chamber and flood the spark plugs (and then the car trunk).

Also, because of this, an oil change after every 100 hours of operation is added to the maintenance of a four-stroke engine.

Carburetor or injector outboard motor?

Engine fuel systems are divided into carburetor and injector engines.

In a carburetor engine, liquid fuel first mixes with air in a separate chamber until it becomes a homogeneous mixture (this process is called «carburation») and only then is sucked into the cylinders.

The design of the carburetor is relatively simple, so the financial cost of purchasing and subsequent maintenance of such an engine is much lower than in the case of injector systems. The carburetor does not require electricity to operate - it only needs the air flow that the engine sucks in.

Carburetors are less demanding on fuel quality.

They can run longer and more consistently than injector engines with obviously bad gasoline. And if clogged, they can be cleaned manually.

A little water ingestion by carburetors also survive without consequences.

But carburetors are much less environmentally friendly than injectors. Without a microcomputer in them, it's impossible to continuously control the composition of the exhaust so that it meets the stringent modern standards. A carburetor engine, however, makes less noise and vibrations.

Alas, carburetors' fuel economy, too, leaves much to be desired in terms of fuel consumption.

Without a controlling electronic system, regardless of engine speed, the carburetor always delivers the same amount of fuel.

It is impossible to compensate it by using diesel instead of petrol - carburetors can be only petrol ones.

Injection systems, which appeared in the second half of the XX century, differ from carburettors by the fact that they force fuel injection into the air flow by means of injectors. An electronic system precisely calculates the necessary dosage.

Two methods are used for this purpose on marine engines: Direct Fuel Injection (DFI) and Electronic Fuel Injection (EFI).

Direct injection is used on both petrol and diesel engines. As the name implies, with direct injection the fuel is injected under pressure directly into the combustion chambers of the cylinders.

The fuel cools the combustion chamber, which has a positive effect on the engine power and lowers fuel consumption and emissions.

With electronic injection, fuel is sprayed into the air flow just before the intake valve of each cylinder.

Unlike direct injection, it is the intake valve, not the combustion chamber, that is cooled. This improves evaporation of the fuel before it enters the combustion chamber.

Injected engines start faster and run more consistently at all load levels.

Injector systems are also reliable. «But if something in them is broken, because of the complex device, it is impossible to solve the problem» on the spot. To diagnose the injectors, you need special equipment from the service center.

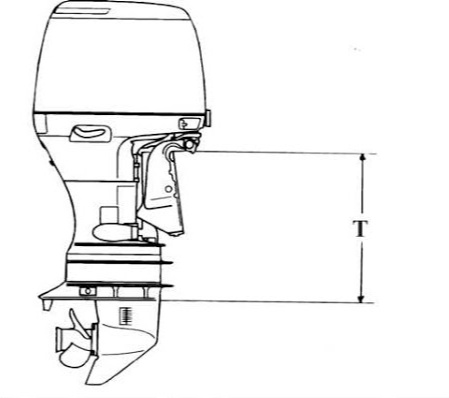

Leg length

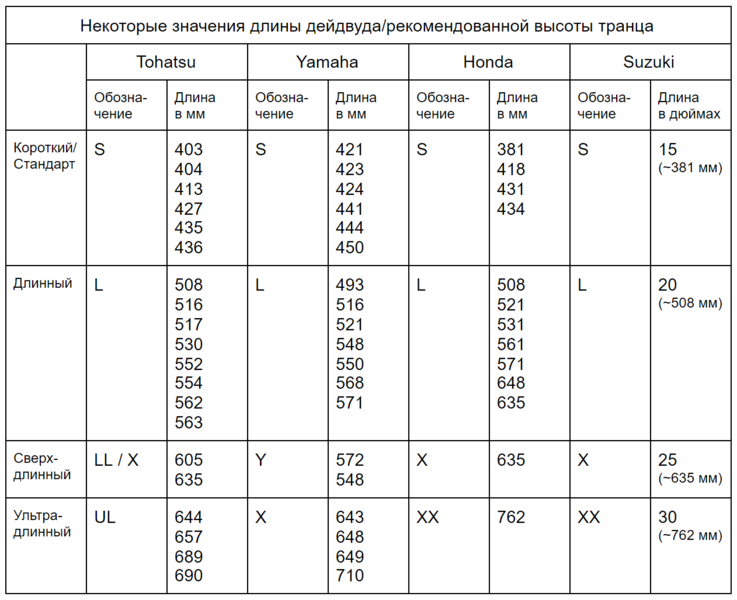

Outboard motors also differ in the length of the shaft and«leg», inside which it runs from the motor at the top of the motor to the propeller at the bottom. The tube that houses the shaft is called «the stern tube». Because of this and the entire «leg» the entire leg is also called «sternwood».

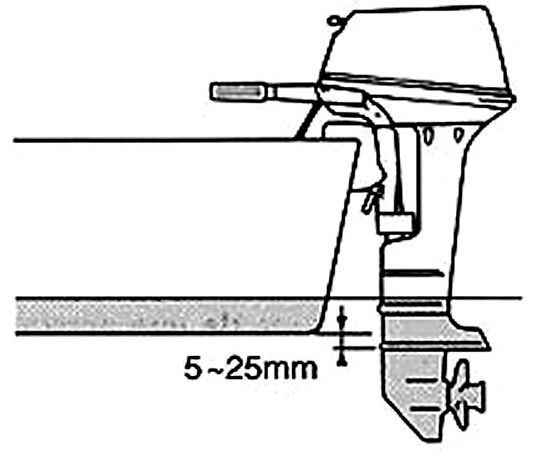

The length of the stern tube must be correctly related to the transom height of the boat - the distance from the top of the transom to the keel.

Motors with a short «leg» are mainly designed for small PVC and RIB boats. However, sometimes they are also used for engines with a large sternwheel.

If you mount the motor too high, the propeller will be subject to cavitation (will start to trap air bubbles) and thus corrosion. In addition, cavitation lowers the boat speed and increases the engine speed. As a result, the engine overheats.

An anti-cavitation plate above the propeller helps prevent cavitation.

But it doesn't work at high engine mounting. Its place is 5-25 mm below the bottom.

Mounting the motor too low is also not a good idea. Because of this the water resistance increases unreasonably. The engine will spend extra energy to overcome the friction, the power will be lost. Also due to the increased draft there is a high risk of accidentally damaging the propeller in shallow water.

There are four types of deadwoods. However, they differ from manufacturer to manufacturer both in designation and length. It is also worth bearing in mind that depending on the manufacturer, the recommended transom height may be given instead of the stern itself.

Propeller or water jet

At the end of «leg» the average outboard engine has an anti-cavitation plate and propeller.

As a basic feature, manufacturers supply an average performance propeller with the engine. It may very likely not be suitable for the loads that await the propeller during operation for a particular owner. So, once you have decided on the engine, it is worth selecting a propeller to go with it. We have already described how to do this earlier.

However, there is another option - a water jet.

Yes, apart from classic stationary water-jet, which can be found on yachts, there is also an outboard water-jet engine. Such models can be found in the segment of motors from 25 to 150 hp from Mercury, Yamaha, Honda, Tohatsu, Evinrude.

The top and«leg» of such engine looks absolutely the same as of any other outboard. But instead of the anti-cavitation plate and propeller underneath, there is a waterboard on the end «leg».

It's also worth noting that the «leg» of a waterjet outboard is very short. The waterjet is located just below the mount by which the engine is hung on the transom.

The advantages of the vodome over the propeller in this case, are the same as on stationary engines. Since the propeller is closed, and the motor (even by the standards of outboard engines) does not go deep into the water, the boat with such equipment can freely walk in shallow water, without fear of catching the rocky bottom and breaking the propeller.

What are the differences between the outboard and a stationary water jet? Let's say at once. Not only in the level of mobility (although this is an important plus for outboards).

The advantages of a stationary waterjet are:

- Better weight distribution due to the location of the motor on the bottom rather than high on the transom

- More efficient water intake system. The same flow that flows around the bottom hits the propeller. There's nothing to slow it down and it continues to move in nearly the same direction, diverting only about 28°. The outboard engine sucks the water from underneath. After hitting the top-down propeller, the flow needs to turn about 90°. Because of this, outboard waterjets are 30% less powerful than stationary waterjets.

- There is no need to lubricate after every 10 hours of operation and no need to clean the bearings after 30-40 hours.

Advantages of an outboard engine:

- A mobile outboard engine with a waterjet instead of a propeller is an ideal engine for fishermen who need to navigate shallow rivers with rocky or snag-filled bottoms.

- There are more boat models on which an outboard motor can be installed than those for which stationary waterjets are available.

- Installing a stationary water jet requires manipulation of the bottom of the boat to install the water intake system. If the boat owner decides to go with a different manufacturer when replacing the engine, complications may arise. Replacing one outboard engine with another is much easier.

It's worth noting that the prices of stationary and outboard watercraft are comparable. For example, the 100hp stationary Alamarin Jet 160 sells for $13,000, while the slightly less powerful outboard Yamaha Jet Drive 90 sells for $10,500-14,000.

Type of control and starting system

On small inflatable boats from PVC, RIB and fishing boats, the outboard engine is started manually, and the boat is controlled by turning the engine in the right direction by the tiller, combined with the throttle grip.

But from 3.3-metres onwards, there are models with a centre console (like the Brig Falcon 330 ), where the throttle is steered and controlled on a separate panel with a steering wheel. Electric start system appears on engines rated from 20 hp.

And the longer the hull length, the more likely it is that the starting and control system, even the outboard, will be remote. On boats longer than 6.3 meters, the tiller is not used at all. An example of one of the largest models of this type can be American fishing boat Lund 2075 Pro Guide.

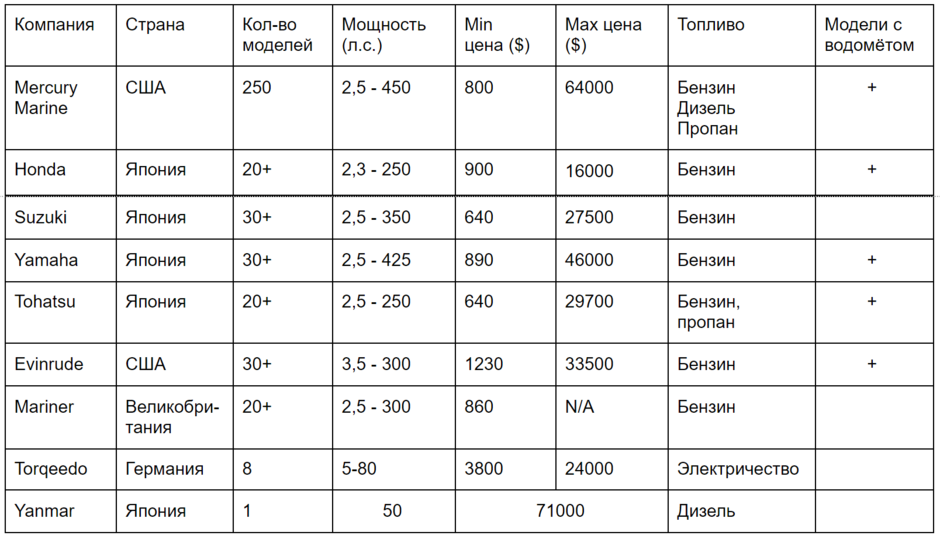

Manufacturers .

Although the leader in the market of outboard motors is the American company Mercury Marine, most of its competitors are Japanese firms.

The cheapest outboard engines on the market are the lowest-power models at 2.3-2.5 hp They will cost $600-800. The most powerful option is the Mercury Racing 450R with 450 hp. The most expensive is the $50hp Yanmar Dtorque 111 diesel for $71,000.

How to save money on an outboard motor?

Having to buy the engine separately from the boat means almost doubling the final cost of the boat. The idea to save money on engine in this situation looks really tempting. And there are at least two ways to do it.

The first is to find a suitable engine on the secondary market.

Buy not a new one, but a used outboard. But for economy of money, you will have to pay with time, which you will have to spend for search of a variant in good condition. Otherwise, the stingy will pay twice, becoming a regular customer of repair shops.

The second way to save money when buying an engine is to give preference to Chinese manufacturers.

Their products are 30-50% cheaper than the models of neighboring Japanese manufacturers. Here is just the quality of materials and assembling at Chinese is often, to put it mildly, awful. So when purchasing such motor you must be very patient, careful and cautious. A detailed guide to the world of Chinese outboards for those who still want to take a chance and take a closer look at them, we published in2019.

Which is better: one outboard motor or several?

Two or even three outboards have a definite advantage. Since their propellers necessarily rotate in different directions, the boat with such a system is easier to moor.

In addition, an independent auxiliary motor or motors is a guarantee that the boat will not be left without an engine in case of breakdown. The chances that two, much less three or four motors will break down simultaneously are much lower.

However, if the choice is between whether to put, for example, one engine at 300 hp or two 150 hp, a significant gain in power, as it may seem at first glance, «multiplication of entities» does not give. But the expenses for refueling and service increase. Two less powerful engines will almost always weigh more than one more powerful engine.

Choosing two engines instead of one makes sense from this point of view if the total power exceeds the capabilities of single engines (as in the example of the Grizzly 960 Unimog we gave above). Also, because of the characteristic reduction of water resistance, twin or inline units allow the boat to accelerate a little faster.