Aluminum Sailboats

Rugged hulls with excellent durability and strength, allowing for safe and reliable navigation in rough waters and challenging conditions.Manufacturers of aluminum Sailboats

The brand Allures produces aft cockpit sailboats and aluminum sailboats. There are 3 models currently in production ranging from 14 to 16 meters. We invite you to explore all current and older models from Allures and contact us for sales and pricing information.

Read more >

The brand Alubat produces aluminum sailboats and lifting keel sailboats. There are 6 models currently in production ranging from 11 to 16 meters. The current model range includes 3 lines: CIGALE, OVNI and OVNICAT. We invite you to explore all current and older models from Alubat and contact us for sales and pricing information.

Read more >

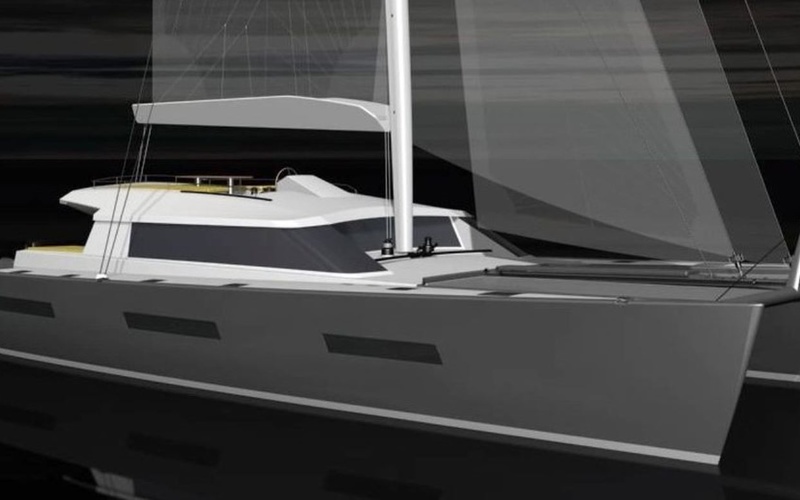

The brand Garcia produces aluminum sailboats and deck saloon sailboats. There are 4 models currently in production ranging from 13 to 20 meters. The current model range includes 2 lines: Catamarans and Sailboats. We invite you to explore all current and older models from Garcia and contact us for sales and pricing information.

Read more >

The brand Andante Marine produces aluminum sailboats and lifting keel sailboats. There is 1 model currently in production of 7.9 meters. We invite you to explore all current and older models from Andante Marine and contact us for sales and pricing information.

Read more >

The brand Bestevaer Yachts produces aluminum sailboats and pilothouse sailboats. There are 7 models currently in production ranging from 10 to 21 meters. We invite you to explore all current and older models from Bestevaer Yachts and contact us for sales and pricing information.

Read more >

The brand Black Sea Yachts produces displacement yachts and steel yachts. There are 12 models currently in production ranging from 14 to 31 meters. The current model range includes 2 lines: Motor Yachts and Sailing Yachts. We invite you to explore all current and older models from Black Sea Yachts and contact us for sales and pricing information.

Read more >

The brand Boreal produces aluminum sailboats and deck saloon sailboats. There are 6 models currently in production ranging from 13 to 22 meters. We invite you to explore all current and older models from Boreal and contact us for sales and pricing information.

Read more >

The brand Crystal Yacht produces aluminum yachts and power catamarans. There are 4 models currently in production ranging from 24 to 50 meters. We invite you to explore all current and older models from Crystal Yacht and contact us for sales and pricing information.

Read more >

The brand Hutting Yachts produces aluminum sailboats and center cockpit sailboats. There are 5 models currently in production ranging from 12 to 16 meters. We invite you to explore all current and older models from Hutting Yachts and contact us for sales and pricing information.

Read more >

The brand JFA Yachts produces expedition yachts and trawlers, motor superyachts and is also active in the superyacht market. There are 35 models currently in production ranging from 5 to 65 meters. The current model range includes 5 lines: Motor multihulls, Motor yachts, Sailing multihulls, Sailing yachts and Tenders. We invite you to explore all current and older models from JFA Yachts and contact us for sales and pricing information.

Read more >

The brand Jongert produces luxury sailing yachts, sailing superyachts and is also active in the superyacht market. There are 7 models currently in production ranging from 18 to 48 meters. We invite you to explore all current and older models from Jongert and contact us for sales and pricing information.

Read more >

The brand MCP Yachts produces aluminum yachts, semi-displacement yachts and is also active in the superyacht market. There are 11 models currently in production ranging from 20 to 44 meters. The current model range includes 2 lines: Motor Yachts and Sail Yachts. We invite you to explore all current and older models from MCP Yachts and contact us for sales and pricing information.

Read more >

Selling Brokers Aluminum Sailboats

Category Description

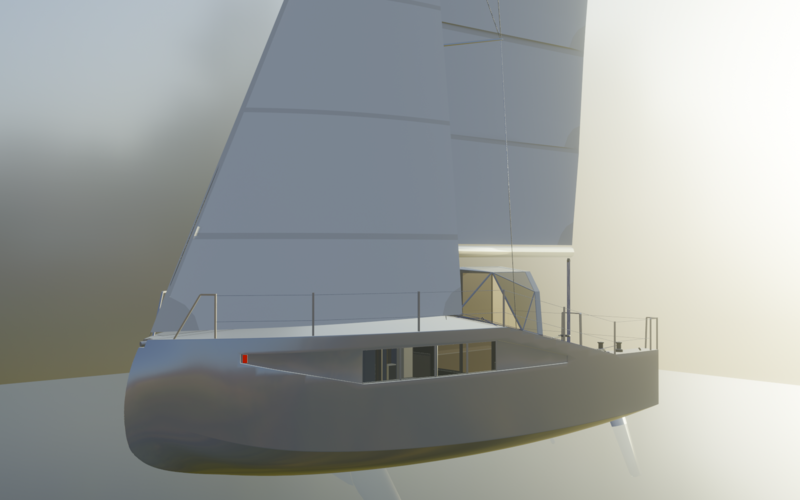

Aluminium sailing yachts are perfect for bluewater cruising. These vessels, characterised by their lightweight yet robust aluminium hulls, offer a unique blend of strength and longevity that appeals to seasoned sailors.

In contrast to fibreglass counterparts, aluminium hulls exhibit remarkable flexibility, bending rather than cracking upon impact, ensuring your yacht stands the test of time. On average, aluminium hulls outlast their fibreglass counterparts by a remarkable 20%, making them the ideal choice for those seeking a yacht with enduring resilience.

While aluminium sailboats may not boast the sleek, shiny appearance of their fibreglass counterparts, their distinctive ruggedness imparts a sense of character that some yachting enthusiasts find alluring. Beauty, after all, is in the eye of the beholder.

It's important to note that aluminium yachts, although renowned for their durability, may lack the same stability as heavier composite boats. Additionally, they tend to heat up quickly under the sun and produce more noise at higher speeds. However, these trade-offs are often outweighed by the sheer strength and longevity of the aluminium construction.

One significant advantage of aluminium boats is their immunity to a common issue in fibreglass hulls—osmosis. Over time, fibreglass hulls can develop small air bubbles that trap water, gradually compromising their structural integrity. With aluminium, such concerns are a thing of the past.

So, how are these exceptional aluminium sailing yachts constructed?

Unlike their composite counterparts, which are produced in standardised moulds, aluminium yachts are crafted on individual frames. This approach allows for unparalleled customisation, enabling yacht owners to tailor the layout and deck spacing to their unique preferences.

The process begins with massive rolls of aluminium sheets carefully cut to the required lengths for each boat. These meticulously crafted pieces are later expertly welded together, forming the sturdy hull that defines these vessels. The finishing touches, including paint application and installation of floors, doors, hatches, helm station consoles, and storage spaces, complete the transformation from raw materials to seaworthy vessels.

Whether you're a seasoned sailor or a newcomer to the world of bluewater cruising, these remarkable vessels offer a unique blend of strength, longevity, and customisation that sets them apart.

Similar categories

184

184

75

75

151

151

160

160

72

72