Hydrogen-powered ground transportation is gradually ceasing to be a gimmick. American analytical company Allied Market Research in 2018 estimated the global annual turnover in the relevant market segment at $651.9 million.

It is projected to grow to $42038.9 million from 2019 to 2026, with a compound annual growth rate of up to 71% in selected regions. Norway plans to ban the use of petrol and diesel engines in Oslofrom 2025 , the UK plans tophase them out nationwide by 2040.

And what happens to boats in the meantime? We tell you!

How hydrogen engines work

Marine engines, of course, can also run on hydrogen (H2). MAN, General Motors (GM Marine Technology), Yanmar and Toyota, for example, have developments related to H2.

Inthe USA, Norway and Scotland, ferries equipped with just such engineare already running or will be running in the nearest future. Dutch shipyard Feadship announced that by 2025 it wants to completely refuse traditional internal combustion engines in favor of hydrogen and electric ones.

Today there are two types of hydrogen engines. They are both found in cars and boats.

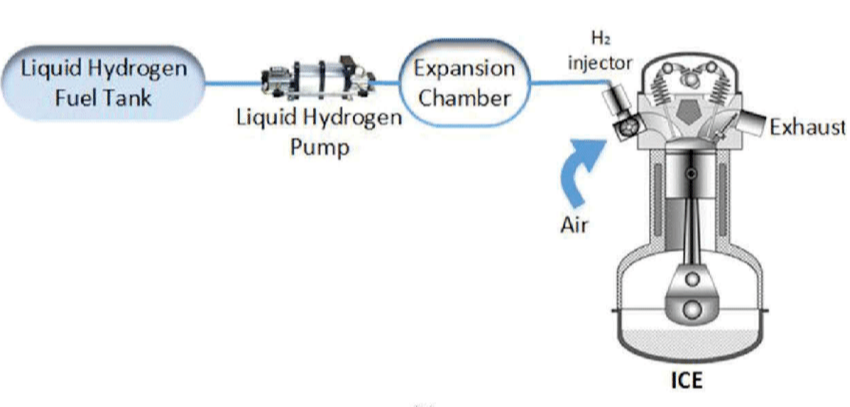

The first type, which uses liquefied H2, is very similar to propane engines. When the H2 mixes with air, it begins to oxidize with oxygen (O2). Simply put, it burns. As a result of the reaction, heat is released, which is converted into electricity and used to run the engine. Only water and engine oil fumes remain in the exhaust.

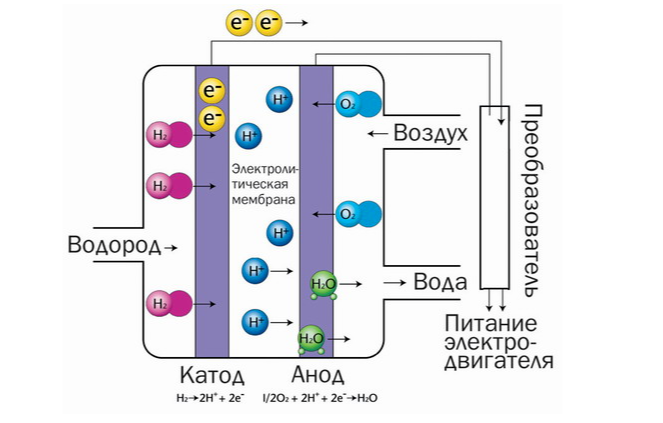

The other type uses fuel cells, which are similar to lead batteries. The cells with an electrode anode (a conductor of electricity with a lack of negatively charged electrons) and a cathode (a conductor with an excess of electrons) of such a battery are separated by a membrane, through which positively charged ions can pass. H2 is supplied to the anode and O2 is supplied to the cathode. At the anode, positively charged H+ ions are formed as a result of the electrochemical reaction. The freed electrons attracted by the anode go to power the motor in the form of electricity. In the meantime, the H+ ions pass through the membrane to the cathode, where they in turn combine with the O2 and the excess electrons from the electrode to form water which can then be reused.

Where does hydrogen come from to fuel an engine?

H2 is not found in nature in its pure form. It is extracted on an industrial scale with several methods: from natural gas and methane, from coal, with nuclear power and even from biomass.

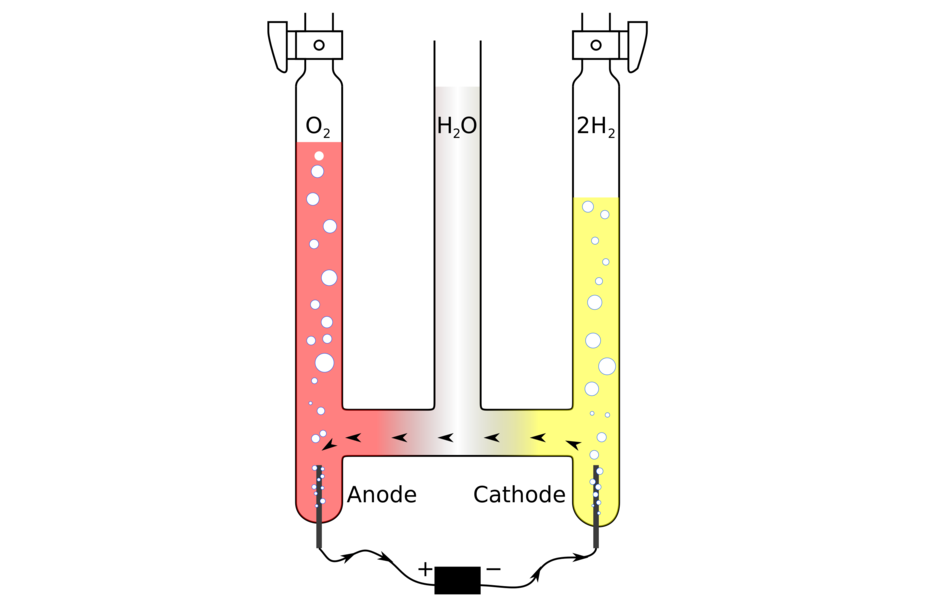

Among these, electrolysis of water is especially worth mentioning. This method is a real boon for shipbuilding as it can be used onboard. Ships have free access to water.

In electrolysis, the water molecules (H2O) are split by electricity at the cathode into O2, positively charged H+ ions and free electrons. The H+ ions are attracted to the anode, where an excess of electrons allows them to be reduced to full H2 molecules.

Which yacht projects are focused on hydrogen engines?

Energy Observer

«Today» 's main test site for marine hydrogen engine technology is the 30.5 metre catamaran Energy Observer. It was built in 1983 and has been used as a sport racing sailing boat for more than 30 years. In 1993, New Zealander Sir Peter James Blake even set a world record for fastest round-the-world voyage. A new page in the catamaran's history began in 2016. The sailboat was completely rebuilt and became a floating laboratory.

In 2017, the Energy Observer crew embarked on a six-year circumnavigation of the globe.

Through 2023, the crew will be testing and improving a wide variety of equipment designed to reduce the yachts' environmental impact.

In 2019, Energy Observer became the first vessel to make an expedition to the Arctic, to Svalbard, using only H2 and renewable energy sources.

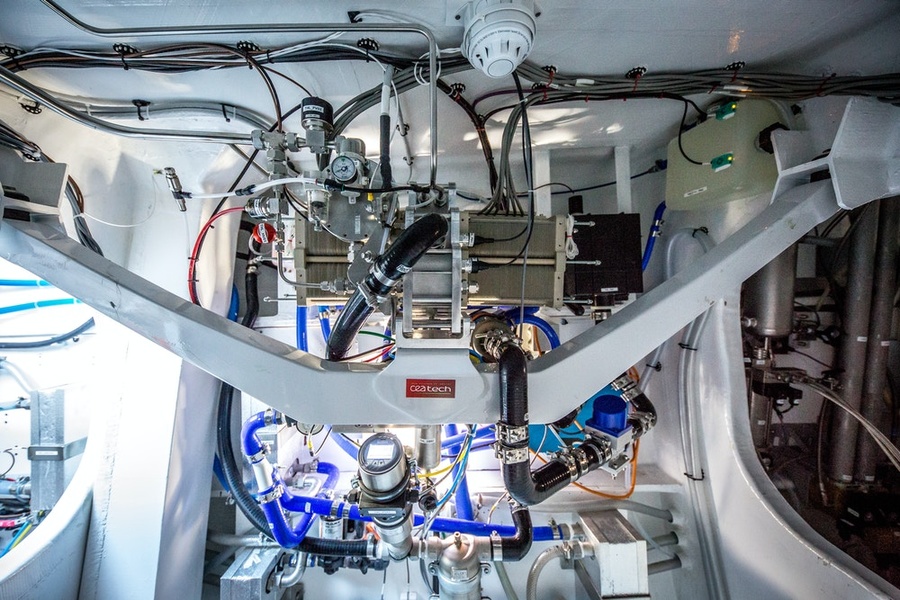

At the heart of the catamaran are hydrogen engines with fuel cells and a seawater electrolysis plant, allowing Energy Observer to be independently and continuously supplied with fuel. From 2020, the catamaran's engines have been replaced by shipboard analogues of the engines of Toyota Mirai, one of the first mass-produced hydrogen vehicles.

The electrolysis units are usually quite bulky, but experts at the French Atomic and Alternative Energies Commission (CEA) have managed to develop a compact version of such a device specifically for Energy Observer. It became part of the propulsion system itself. Up to 4 normal cubic metres (nm³) of pure H2 can be produced per hour on board a catamaran from 3.66 litres of treated water.

The purified water is also obtained from seawater directly on board Energy Observer. It takes 250 watts of electricity to desalinate 90 litres of potable water. Of these, 30 litres are used for electrolysis and to produce H2, which will help generate electricity again.

For 2018, the electrolysis unit ran for about 1,500 hours and produced 488 kg of H2. The product yield was at 42%.

The Energy Observer can store up to 63 kg of H2 at a time.

If on board, that would be enough to provide enough electricity for about 40 days for a family of four living in a house of about 140 m².

Enough even for electric heating. The heat released by the engine at Energy Observer is used to heat the cabins and heat the water.

In addition to the hydrogen engine, Energy Observer is also equipped with solar panels and a pair of Oceanwings automated turning rigid sails from design studio VPLP. The total area of the solar panels exceeds 200m² and the area of each sail exceeds 31m². The catamaran also gets its electricity from hydroelectric generators, harnessing the power of the ocean current.

The power of the two Energy Observer engines is 115 hp and the catamaran has an optimum speed of 4.5 knots. On further acceleration, power consumption begins to increase exponentially. The maximum speed the vessel reached was 12.7 knots.

Planet Solar/Race for water

A small hydrogen engine also powers the world's largest solar-powered catamaran - the 35-metre Planet Solar.

Unlike Energy Observer, it was built like the one you see today.» Back in 2004 the Swiss explorer Raphaël Domjan had a vision of a round-the-world voyage, during which he could promote «green technology.

Four years later, in 2008, thanks to funding from German entrepreneur Immo Ströher and New Zealand naval architect Craig Loomes, construction of a catamaran for the projectbegan in Kiel. The work took two years to complete and Domjan set off on a two-year tour in the spring of 2010.

Now the catamaran crew is nearing completion of a second round-the-world tour called «Race for water» («Race for water»). Since 2015, the vessel itself has had the same name. During the stops, the crew talks about ways to use plastic to generate electricity. The expedition started in 2017 and is scheduled to run until 2021.

About 70% of the time Planet Solar is moving at an average speed of 4 knots powered by an electric motor, the batteries for which charge solar panels with a total area of more than 500 m². When needed to accelerate to 8 knots or simply to refuel, the Planet Solar pulls a 40-metre sail-kite which is launched up to 150 metres.

The 200kg of H2 is stored on board in the form of 25 compressed gas cylinders.

These can be converted into around 2600 kW of electricity - 4 times more than the on-board batteries store.

On H2 alone, a catamaran can sail continuously for 6-7 days at 5 knots, even when there is no sun. But this is more of a last resort option. Since April 2017 less than 20% of the time was spent on the H2.

As on Energy Observer, the crew can replenish the H2 on their own directly from the seawater.

Acionna

The most ambitious megayacht concept using H2 as fuel is the 175-metre, eight-deck Acionna project. It was unveiled by British designer Andy Waugh during the Monaco Yacht Show in September 2018. But so far the project has not been followed up.

Energy Observer and Planet Solar have already proven that hydrogen engines make it possible to travel on water even around the world. Acciona, too, will be designed for long cruises.

The main obstacle to the project's implementation is the lack of infrastructure for fueling such a vessel in the world.

«Only a few offshore hydrogen refueling stations are planned. But as long as ships like this are not built, the demand for hydrogen will not increase. There will be no way out of the chicken and egg impasse. Building hydrogen refuelling stations is not economically viable until there is demand from the many hydrogen-powered boats»," Waugh said.

Whether H2 will be at least partially generated directly on board has not yet been mentioned.

Aqua

Exactly one year after the presentation of Acciona, another H2-powered megayacht concept was presented to the public during the 2019 Monaco Yacht Show. The 112-meter Aqua is inferior to Acciona in length but has an even more impressive exterior design. It was given to the boat by the Dutch studio Sinot Yacht Design & Architecture.

Lateral Naval Architects is responsible for the naval architecture and engineering calculations in the project team. The vessel will use both fuel cells and liquefied H2 to power both the engine and all electrical systems. It will be stored at -253 degrees Celsius in two 28-ton vacuum tanks. It took the specialists 5 months to work out all the details.

It is expected that Aqua will be able to sail up to 3,750 nautical miles at an average speed of 10-12 knots without refueling. The maximum speed will be 17 knots - almost 5 knots more than Energy Observer which is 3.7 times smaller than Aqua.

Almost immediately after the presentation of the project, rumors swirled that Microsoft founder Bill Gates had ordered the construction of the yacht.

He was said to have allocated $650 mn for the construction. However, Sinot refuted these rumors saying that Aqua is still under construction and was not sold to Gates or anyone else.

Waterecho

Renowned Norwegian designer and naval architect Espen Øino has designed at least two H2 yachts in the last couple of years. Both are definitely worthy of mention in this selection.

Let's start with the bigger one - the 65 mt Waterecho - which Espen Øino designed together with VSY and Dante O . Benini & Partners Architects. The project was unveiled in the fall of 2018.

What sets this Waterecho apart from Aqua and Acciona is not only its size, but also its more realistic approach to project feasibility. VSY places serious emphasis on sustainability, but the fuel cell hydrogen engine on this yacht is a nice addition rather than a key feature. Although the yard has an agreement with Siemens and Lloyd's Register that will allow the adaptation of Waterecho for H2, it is not mentioned in the specifications of the yacht published on VSY's website.

Instead of hydrogen engines in the relevant column a pair of conventional Caterpillar 3512 °C diesel engines of 2400 hp each is listed, and diesel generators (albeit of the latest generation) are planned for power supply. The fact that diesel is the main option for Waterecho is also indicated by the mention of an exhaust cleaning system for the engines and generators.

Top speed (16 knots) and range (5,000 nautical miles at 12 knots) are also listed for diesel.

H2-Yachts

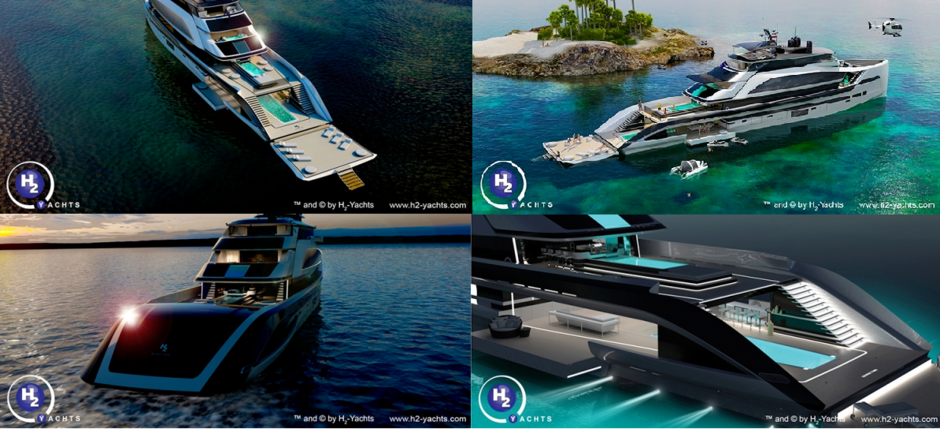

Swiss company H2-Industries AG has created its own liquefied H2 generation and storage system, LOHC (liquid organic hydrogen carrier). In 2014, studio H2-Yachts, a division of H2-Industries, unveiled a concept for an autonomous 62.2-metre explorer yacht with a vertical bow that could use this technology. The design was developed over a four-year period in collaboration with Spanish naval architect Michael Stusch and the Austrian studio Motion Code: Blue, which designed the submarine Migaloo.

A pair of Voith-Schneider (VSP) cycloidal transmission shafts of 500 kW each was proposed as the main propulsion force. The expected volume of the tanks for generation from water and subsequent storage of H2 and refuelling of the fuel cells was to be 250,000 litres.

This was calculated to give the yacht a bareboat range of over 5000 nautical miles.

She could travel at a maximum speed of 13 knots.

The 850 m² solar panels were to be retractable and extendable on the roof to provide solar storage and also to function as a sunshade. The power would be stored in six solar batteries with a total capacity of 1MW.

Blue Angel

Another H2 yacht concept unveiled in 2019 was the 36m Blue Angel from Dutch studio Diana Yacht Design and Belgian company Exmar Yachting.

Exclusively hydrogen fuel cells are expected to power the boat during short voyages. So Blue Angel can sail continuously at speeds of up to 12 knots for up to 18 hours.

And for longer distances the boat will be a hybrid, augmented by diesel generators.

Hynova 40

While other boats for the most part remain concepts, this 12.2m open-top boat from the French yard Hynova Yachts is poised to turn a new page in the history of H2 yachting and become the first production model of its kind. The current prototype was scheduled to be unveiled at the cancelledCannes Yachting Festival 2020 due to COVID-19.

This project is in fact a direct result of the research that has been carried out on board Energy Observer in recent years. The team has been closely involved in the development of the Hynova 40.

A pair of Toyota's fuel-cell-powered engines will propel the 12-person vessel to 25-30 knots.

Cruising speed will be 15-20 knots. Owners will have a choice of 150 or 210 kW (203 or 285 hp) engines.

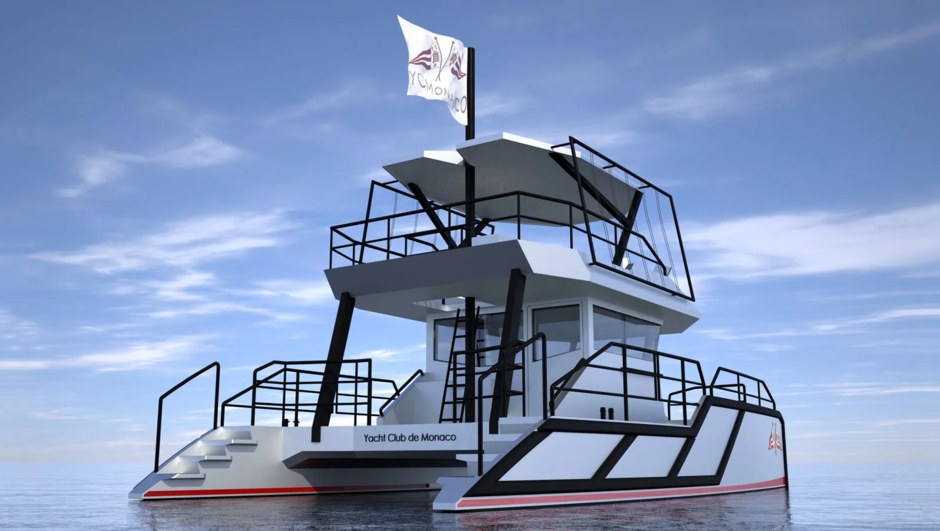

Judge's boat for Monaco Yacht Club by Espen Oino

In 2019, Espen Oino was asked to design an eco-friendly boat for the Yacht Club de Monaco for sailing competition referees. The engineering calculations for the project were carried out by Dario Calzavara.

The result is a 12-passenger aluminium 11.5-metre catamaran which can be used not only for regattas but also for cruises to observe marine mammals.

The main propulsion system will be a pair of 100kW (134hp) YASA motors powered by solar panels on the roof. They will enable the boat to speed up to 17 knots. At the speed of 15 knots the battery charge is enough for 3 hours of continuous running. Electric motor can be supplemented by sails and H2 generation system.

The catamaran was expected to be launched in 2020. But, apparently, the COVID-19 pandemic has made its adjustments. There is still no news on the boat's readiness.

Catamaran by Cheetah Marine

But another, a 9.95-metre hydrogen catamaran from British shipyard Cheetah Marine underwent sea trials back in 2016. Work on the project took three years. The final version was fitted with 135 hp Honda outboard engines, which ran on liquefied gas rather than fuel cells. At the time it was one of the first, if not the very first example of using this type of engine for a boat.

During sea trials, the catamaran traveled 56 nautical miles at an average speed of 7-8 knots. At its maximum, the boat accelerated to 12 knots. The catamaran reached the finish line even 3 hours earlier than expected: instead of 12 hours it took 8 hours. Of the 15 kg H2 on board, only 6.6 kg were used up, so the remainder would be enough for one more such voyage.

To cover the same distance using a fossil fuel engine would have required 32 litres of fuel. 6.6 kg of H2 corresponded to 25 liters of fuel.

The H2 for the boat was produced from seawater at Cheetah Marine on the Isle of Wight. Solar panels were adapted to power the plant.

Phil Sharp's OceansLab

Not only owners and builders of motor yachts are interested in H2 as a fuel, but also people who like sailing boats.

British yachtsman Phil Sharp is a two-time Class 40 world champion who has already set three world speed records since 2016. But apart from that he is also a professional mechanical engineer. As of 2019, Sharpe is combining these two roles in his OceansLab project, which aims to bring cutting-edge «green» technology even to yachts competing in the toughest ocean races like The Ocean Race and Vendee Globe circumnavigators. Sharp hopes to be a pioneer in the coming years.

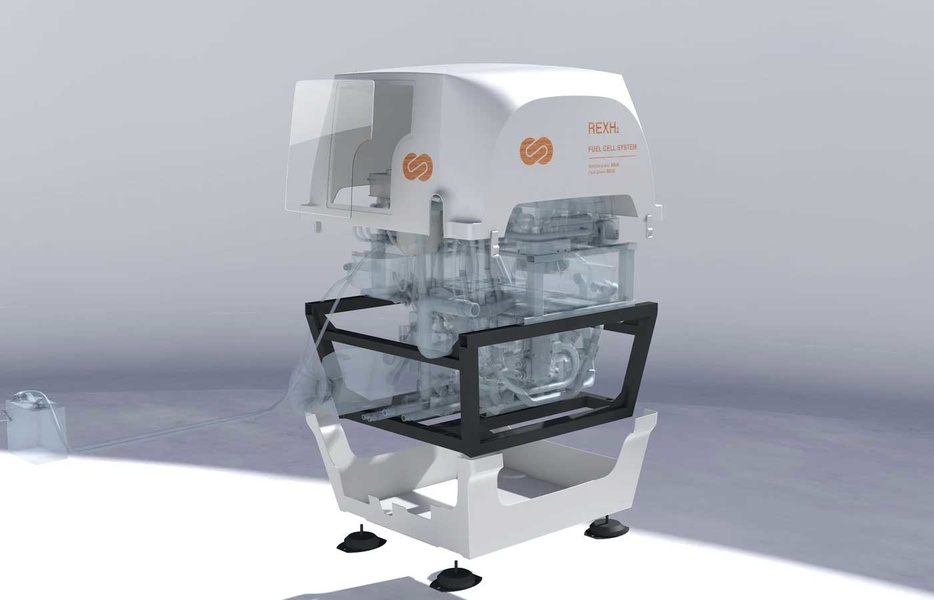

Thanks to Ocean Lab, the Genevos hydrogen power module has already been developed, which could replace the diesel generators needed to run the electronics on sailboats. When mass-produced, the modules will have a capacity of 8 to 200 kW. Work on storage for the H2 is still ongoing.

The future is already here. Or is it not?

Hydrogen engines are not a perfect technology. Like any device, it has its strengths and weaknesses.

Advantages

- Hydrogen is the most abundant chemical element in the universe.

- High efficiency.

Hydrogen is light and its energy capacity is 3 times higher than traditional fuels.

- Economy.

Mikhail Kasatkin,head of the department of the chief designer of the hydrogen energy sector of the Russian Central Research Institute for Ship Electrical Engineering and Technology (TsNII SET), in an interview in 2019, compared the costs of operating machinery running on gasoline and on H2:

«Hydrogen is produced from natural gas at a cost of 6 rubles per 1 m³, the cost of one kWh of electricity in the power plant comes out about 1.5 rubles <...> If we talk about trucks, with gasoline at 40-50 rubles per liter. It turns out that the truck, taking into account its efficiency, spends, on average, 16 roubles per 1 kilowatt-hour of electricity <...> In the shipbuilding industry the same cost. Ships will see big savings if we use a hydrogen fuel cell power plant. According to my calculations, a 4 MW unit with a monthly sailing time will save a ship 200 tons of fuel».

- Eco-friendliness.

Hydrogen fuel allows the engine owner not to contribute to intensification of greenhouse effect on the Earth, because after its combustion neither methane (СН4), nor carbon dioxide (СО2), nor oxides of nitrogen (NOx) are formed. This quality is becoming increasingly important as regulations tighten on emissions from marine engines.

- H2 engines are virtually silent.

- Service life of hydrogen fuel cell is much higher than that of conventional electric battery: not 3-5 but 8-10 years.

- Autonomy is potentially longer than that of an electric motor.

As it is difficult to judge about the range of ships so far, let us compare car parameters. An electric car can travel a maximum of 610 km on a single charge (Tesla Model S). At the same time, for example,Toyota Mirai of the second generation with an engine running on hydrogen fuel cells can already overcome 650 km. This value does not depend on ambient temperature.

However conventional electric motors are massively superior to hydrogen engines (at least for now).

«In my opinion electric motors have more potential for development and efficiency. At the moment, hydrogen engines have no advantages over electric motors. Range, fueling price, safety, power and acceleration - electric motors win everywhere compared to hydrogen cars. The only advantage is very fast refuelling. And when they invent a faster method of filling electric cars, hydrogen cars will step back», - says designer, head of «ANGSTROM BUREAU - houses on pontoons» Stanislav Azarov, whom itBoat asked to assess the prospects of hydrogen fuel use in the yachting industry.

Stanislav also made a bet on the development of electric, not hydrogen engines for water transport.

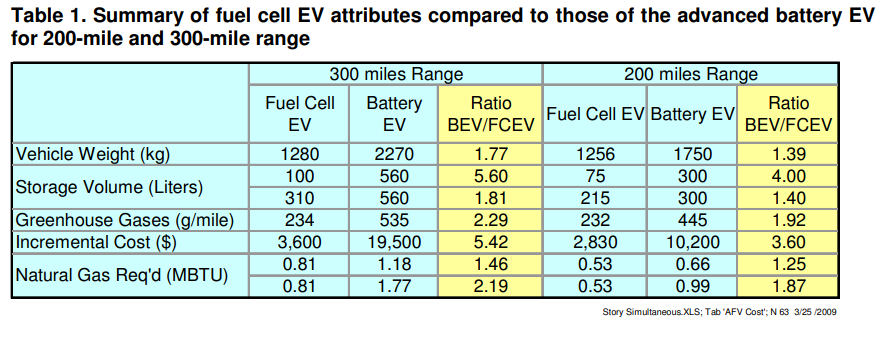

- An engine powered by hydrogen fuel cells weighs less than a comparable electric motor which can travel the same distance without a recharge.

Even greater is the difference between the amount of energy storage required on board. How different these parameters are is shown, for example, in the comparative table in the report by Sandy Thomas, President of H2Gen Innovations, which was published on the website of the US Department of Energy.

Disadvantages

- Gaseous H2 is explosive.

Damage to the storage of liquefied hydrogen and the beginning of its evaporation (it is enough temperature +7 ° C) will put the ship in jeopardy. The mixture of H2 and O2 is not called «rattlesnake gas for nothing». It is highly explosive. Flammable gas even at normal atmospheric pressure may ignite from the slightest spark. It burns instantly, with a pop, as if exploding.

«In case of a small leakage we can be left in the middle of the ocean without fuel at once», - warns Stanislav Azarov.

At that, H2 is colorless and odorless, moreover it can penetrate straight through the walls of containers, where it is stored. To detect its leakage is extremely difficult.

- The infrastructure for refuelling H2, and even more so for refuelling ships, is still extremely underdeveloped.

As of 2019, there were only about 300 charging stations per 5,000 H2-powered vehicles worldwide. By 2030, the number of charging stations is expected to increase by about an order of magnitude. Building each such station will require an average of $1 million.

«If we are talking about onshore refueling, we need a network of such stations, which requires colossal investments in various countries and remote regions. And this is one of the main pillars, why hydrogen technology is developing so slowly in the automotive industry», - said Stanislav Azarov.

- Industrial production of H2 is either expensive or not environmentally friendly.

According to Stanislav Azarov the most important factor hindering wide implementation of hydrogen technologies is high cost of H2 production, as well as components for its storage and transportation.

«Gas transportation and storage require use of expensive materials and high quality mechanisms, and the aqueous environment is very dynamic and unstable», - the expert says.

It is not to say that there are no ways to produce H2 on an industrial scale today. It is widely used in the production of many organic substances required in a wide range of fields: from food industry (margarine) to space industry (rocket fuel).

The cheapest and most mature industrial method for producing hydrogen is from methane, which in turn is produced from natural gas or coal. Thus, more than 68% of H2 is produced in the world, while only 5% is produced by electrolysis.

However, the transformation of methane is associated with significant CO2 emissions. « Carbon Footprint» (the sum of all greenhouse gas emissions from production) of H2 based on methane from natural gas is comparable to that of natural gas. And for H2 derived from«coal» methane, this figure is 2.5 times higher.

At the same time, the cost of «green» H2 obtained by electrolysis is 2-5 times higher than that obtained from natural gas. Electrolysis using electricity from renewable energy sources is still the most expensive technology of H2 production. Currently, the maximum cost to produce 1 nm3/h by this method is almost €9000.